Table of contents of the page

En Ok Pool Reform from this page within Pool filtration and Pool purifier We want to explain the charge for water treatment: Pool ceramic microfiltration.

What is pool filtration

Pool filtration is the procedure for disinfecting pool water., that is, the cleaning of particles that may exist on the surface and in suspension.

So, as you can already see, to keep the pool water in perfect condition at the same time it is necessary to ensure correct pool filtration.

Also another essential measure to preserve pure and clean water is to maintain pH control and therefore apply a good pool water treatment.

When pool filtration is necessary

Pool filtration is always necessary to a greater or lesser extent (depending on water temperature).

Problems associated with traditional water filtration

What is the pool purifier?

What is the pool purifier?

Summary of what a pool treatment plant is

- Basically, and very simply put, The pool purifier is the mechanism for cleaning and purifying the water, where dirt is retained thanks to the filter load.

- In this way, we will obtain treated and properly clean water so that it can be returned to the pool.

- Finally, check out more details on their specific page: pool purifier.

Disadvantages of water disinfection with the traditional system

1st Disadvantages of traditional pool water treatment: POOR FILTRATION

- Deficiency in particle retention, allowing all substances of, in general, less than 20 microns to pass through.

2nd disadvantage: MATERIALS USED

- The interior tubes and nozzles use less robust materials that break and allow filter material to pass through (granular materials and mobile beds) that can clog the circuit and reach the pool.

3rd impediment: COMPLEX INCIDENTS TO RESOLVE

- Incidents require stopping the installation partially or completely and emptying and refilling the system, with the consequent economic, energy and water costs.

4th obstacle: DISINFECTANT CONSUMPTION

- Sand filters end up harboring retained particles and worsen the disinfection of the pool because they consume chlorine, generate biofilm and can harbor dangerous bacteria.

5th drawback: THEY REQUIRE A LOT OF SPACE

- Traditional filters are very bulky and weigh a lot, so you must have a surface that can support their weight added to that of the water. And, it also generates difficulties when being replaced.

What is ceramic pool microfiltration?

Ceramic pool filtration what is it

Standard filtration systems are ineffective in removing waste.

Standard filtration systems, using sand filter beds or other filter media, have proven to be ineffective in eliminating the products brought into the pool by bathers and, above all, they are pollution retention elements that serve as support for bacteria and viruses that are protected in the biofilm.

Ceramic microfiltration pool with Keramikos

Ceramic microfiltration for swimming pools is the most vigorous with water disinfection

Ceramic Microfiltration at 3 microns is the most effective system for removing solids, considerably reducing the formation of byproducts. Other advantages are the saving of water, energy and chemical products for definfection.

The system is fully automatic and managed via the Web

Ceramic pool microfiltration with Keramikos: robust system ROBUST SYSTEM

The membranes are built in ceramic material, resistant to temperature, pressure, pH changes and the use of chemicals as disinfectants and cleaners. For their part, components such as valves, housings, collectors... are made of polypropylene, a very resistant material. All this makes it a robust system with a long useful life.

In media filters, the filter material is protected by accessories that weaken and break over time, allowing the filter material to escape.

The Keramikos ceramic pool filtration device has improved its size

The pool ceramic microfiltration equipment has high performance in only 2,7M2-150M3H

All the Recent versions of Keramikos have made great improvements in space optimization, managing to reduce the necessary space to 1,15×2,3m.

This is a significant saving in installation space dedicated to filtering, since equivalent sand or glass filters would require 3 or 4 times that space (12m2 and 15m2).

Reducing space does not decrease performance

And with these measurements, Keramikos filters 3 µm. at a flow rate of 150m3/h, equivalent to a 600m pool3 of volume.

With 2 filters with a diameter of 2000mm. The same flow rate is passed at a filtering speed of 25 m/h. and with 2 filters with a diameter of 2350mm. the speed is 20 m/h.

What is Keramikos ceramic pool microfiltration like?

Keramikos ceramic pool microfiltration operation

What improvements does ceramic microfiltration provide in swimming pools?

They remove more load from the water and eliminate it down the drain

- Thus reducing the demand for chlorine, the formation of byproducts and improving the quality of the water and the pool environment.

Water stability

- Depending on the daily uses of the pool. In this way, a proportional renewal of the water is carried out through washing; achieving more stable water and avoiding irritation to users.

By improving water quality

- It also improves the environment, reducing respiratory problems for users and workers and corrosion problems in the facilities.

Filtration quality

- In ceramic membranes the substrate is fixed, offering a constant filtration degree which does not vary depending on the filtration speed. The membrane has one side that retains substances and allows clarified water to pass through. In the cleaning process, the retained substances are eliminated through the countercurrent drain.

- Additionally, it includes automatic coagulant dosing, which helps retain smaller particles such as colloids found in water.

Saving water and energy

- The membrane system uses 300 liters to wash the filter for a 400m pool3. When new water is added to the pool it is a small volume that does not influence the water temperature, reducing energy consumption in heating the pool.

Higher recovery rate

By improving filtration, reducing water substances such as oils, fats and organic matter, the formation of by-products such as chloramines and chloroform is reduced, water quality is improved, water expenditure for washing the filter material is considerably reduced, thereby that we achieve significant savings in water and thermal energy. This improvement means that The recovery rate, or percentage of water that is dedicated to washing the filter, is greatly reduced, compared to traditional filtration systems.

Cleaning and disinfection of filter material

When the pressure difference between the inlet and outlet of the ceramic filter is not recovered in the air and water washes, a chemical wash is automatically activated that eliminates the substances adhered to the filter material and the biofilm, thus recovering the entirety of filtration capacity, reducing the formation of byproducts such as chloramines, chloroform and the formation of biofilm, which are generated in other standard filtration systems.

Automatic system, without stops

The filtration system works fully automatic and autonomous, thanks to a PLC that manages all filtration, cleaning and product dosing operations.

Washing and disinfection processes are automated, When a Membrane is cleaned the rest continues filtering, no filtration stops are required, nor intervention of maintenance operators in the cleaning. The maintenance operator only has to carry out stock checking and operation review tasks.

Information registration with Smårt-AD

- All processes can be monitored from a control panel thanks to the fact that the PLC has an integrated web server that allows access to information in person or remotely through any mobile device or computer with an internet connection. It has a record of the operating parameters, pressure, recirculation flow, renewed water, pH, chlorine, etc. In addition, warnings and alarms can be configured to predict and solve possible incidents.

Reduction in weight and space required

- When it comes to the design and projection of a facility, the space required for the facilities increasingly counts more and more. With Keramikos, we reduce the space necessary for its installation; Additionally, it enters through standard doors, allowing it to be installed when a filter media needs to be replaced. weight per m2 is considerably reduced, so in many cases the high cost of reinforcing the engine room structure to support the weight of a standard filter is avoided.

- HIGH PERFORMANCE

- IN ONLY 2,7M2-150M3H

- The latest versions of Keramikos have made great improvements in space optimization, managing to reduce the necessary space to 1,15×2,3m. This is a significant saving in installation space dedicated to filtering, since equivalent sand or glass filters would require 3 or 4 times that space (12m2 and 15m2).

- Reducing space does not decrease performance, and with these measures, Keramikos filters 3 µm. at a flow rate of 150m3/h, equivalent to a 600m pool3 of volume. With 2 filters with a diameter of 2000mm. The same flow rate is passed at a filtering speed of 25 m/h. and with 2 filters with a diameter of 2350mm. the speed is 20 m/h.

Quick return on investment

- The savings in water, energy and products achieved with this system allow the initial investment to be recovered much more quickly, despite being higher than for other systems.

- FAST RECOVERY OF INVESTMENT

- The change to ceramic filtration means savings in water, savings in energy, possibility of recovering energy, savings in chemical products, reduction in maintenance work, reduction in repairs and change of filter material, etc. All this means that even in less than 1 year, the investment difference is recovered.

Kermikos pool ceramic filtration system in constant development

Testing new ceramic membranes for pool water purification

New ceramic membranes in testing phase

Within our constant process of research and improvement of the materials that we recommend to our clients, we are currently testing in our pilot plant new ceramic membranes that are immersed in a tank, taking up very little space.

What will the new ceramic membranes for swimming pools be like?

- Above all, the new ceamic membranes for swimming pools are intended to replace media filters, polymeric micro- and ultrafiltration systems, recover gray water and wastewater treatment plants for use in irrigation and non-sanitary uses or in contact with food.

- They are very robust, easy to install and have a long useful life.

- They offer automatic processes and it is possible to maintain high levels of quality in filtration over time.

Buy ceramic microfiltration system for swimming pool

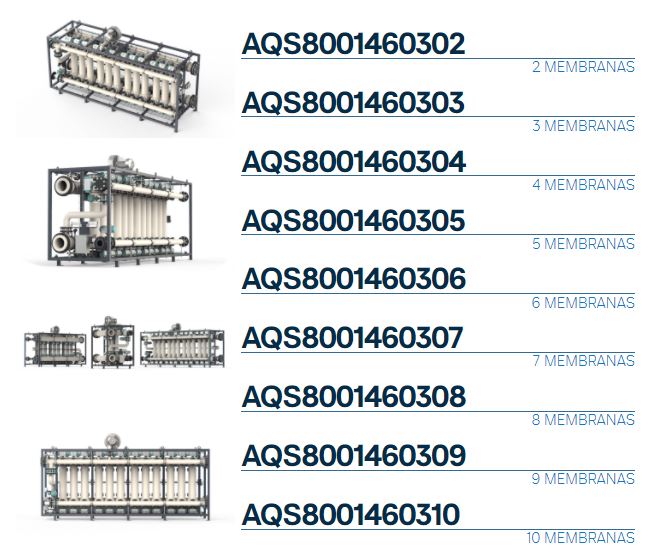

Repertoire of ceramic microfiltration pool models Keramikos Oxidine

Contact Oxidine pool water treatment system with ceramic

From Ok Pool Reform, we recommend the company Oxidine with its Keramikos pool ceramic microfiltration system,.

Ceramic membrane filtration for Crystar pool

What is ceramic membrane filtration for Crystar pools?

Crystar® dead-end membrane filtration technology

Saint Gobain's patented Crystar® FT dead-end technology uses multilayer recrystallized silicon carbide (R-SiC) membranes carried by a unique monolithic honeycomb geometry, which is also made of porous R-SiC.

How Crystar pool ceramic membrane filtration is designed

Result blends superior properties of R-SiC and ultra-compact honeycomb geometry

membrane layers

Crystar® Filtration Technology (FT) and Air Filtration Technology (aFT) are engineered with silicon carbide (SiC), an exceptional ceramic material with a myriad of advanced mechanical, thermal and chemical properties.

Recrystallized SiC (R-SiC) material is a special grade of SiC obtained through a sublimation/condensation process at temperatures above 2000°C.

This process removes nanoparticles to create a microstructure with excellent permeability to various fluids.

Thanks to the well-controlled and engineered microstructure of high-purity R-SiC from membrane to support, Crystar® FT membranes and filters feature:

How Crystar dead-end membranes work

Superior, innovative dead-end filtration with Crystar® FT

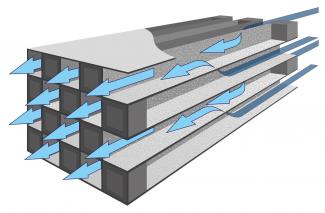

Crystar® FT dead-end membranes are high-functional products designed with alternately capped channels that define flow paths for feed and permeate streams.

The filtration membranes have external dimensions of only 149 x 149 x 1000 mm, providing 11m2 of filtration surface thanks to their internal honeycomb geometry. This compactness cannot be exaggerated.

Crystar dead-end membrane operating phases

- First, liquid enters the inlet end axially through the open channels. The inlet channels are plugged at the other end, forcing liquid to flow through the membrane coated onto the porous honeycomb walls.

- After flowing through the membrane, the filtered liquid leaves the monolith axially through the outlet channels.

- Finally, the low thickness (1,9 mm) and high porosity (40%) of the walls offer low resistance to fluid flow, allowing for highly efficient liquid filtration and backwashing.

Key Benefits of Crystar® R-SiC Materials

Improved permeate flows at reduced pressures for lower energy consumption

- Fast, low-water backwash operations: Ceramic membranes for recreational water filtration can dramatically improve the cleaning and disinfection processes of swimming pools, spas and wading pools.

- High thermal conductivity, low thermal expansion and high mechanical resistance. This allows for shorter high temperature cleaning cycles without risking damage to the structure of the filter media.

- Superior thermal and chemical resistance to corrosive agents from pH 0 – pH 14, allowing the use of aggressive cleaning agents and filtration of aggressive fluids.

- The honeycomb geometry also allows for fast backwash cycles with low water consumption.

- Only 30 to 80 liters are needed during a 3 to 5 second backwash to clean a Crystar® membrane.

- Frequent backwashing of filtration membranes contributes to the reduction of chloramines and trihalomethanes, reducing skin and eye irritation, as well as the risk of diseases such as asthma and allergies due to prolonged exposure to these chlorinated compounds.

- Finally, the high permeability of recrystallized silicon carbide allows for low pressure operation, typically in the range of 0,1 to 0,5 bar (1 to 5 meters water column). Filtration membrane elements can be incorporated into vacuum or pressure housings depending on application requirements.

They reduce the risk of bathers encountering harmful microorganisms

- Low adsorption of organic matter and other negatively charged compounds, thanks to the inherently negative surface charge of R-SiC, enabling fast and efficient cleaning procedures in highly fouling liquids, such as those with natural organic matter (NOM) content.

- Excellent retention efficiency, with demonstrable success in reducing high levels of suspended solids, bacteria, oil and other particles in challenging streams.

- Such as legionella, cryptosporidium and giardia, while improving water quality by reducing aggressive compounds such as chloramines and trihalomethane.

- A physical barrier against microorganisms

- Crystar® ceramic membranes feature 40% open porosity with membranes as small as 0,25 micrometers (µm) pore size.

- As a result, it offers a unique combination of water permeability with microorganism retention efficiency that is greatly improved over standard pool filtration systems. The stability of the ceramic silicon carbide microstructure provides a reliable filtration barrier, unlike granular media filters, which can be subject to gradual degradation and loss of efficiency.

A compact and environmentally friendly filtration technology

- Crystar® ceramic membranes filter pool water through a unique dead-end honeycomb architecture of parallel channels with a stable and well-designed porous microstructure.

- This specific geometry presents a very high filtration area in compact filtration membrane elements (11 m2 in a 149 x 149 x 1000 mm filtration membrane element).

- Combined with the modular design of filtration systems, Crystar filtration technology is the perfect solution for installing or upgrading filtration systems in limited or hard-to-reach spaces.

- And, also to provide safe and enjoyable pool water with significant savings in operating costs.

Models of ceramic membranes for swimming pools

The Crystar® HiFlo ceramic pool membrane

- (4 µm pore size), for example, can retain chlorine-resistant Cryptosporidium and Giardia protozoa with 99,996% efficiency.

- Outbreaks of these dangerous microorganisms have caused the closure of multiple swimming pools around the world. Crystar® HiFlo shows an excellent trade-off between water filtration capacity and filtration efficiency.

Crystar® HiPur The Crystar® HiPur pool ceramic microfiltration membrane

- (0,25 µm) can filter Legionella and Pseudomonas Aeruginosa with a measured efficiency greater than 99,999% and viruses with an efficiency greater than 98%.

- This product is suitable for filtration of therapy and spa pools, providing sanitary and excellent water, with a low need for chemicals, for the comfort and enjoyment of bathers.

Buy ceramic membrane filtration for Crystar pool

Contact Crystar Filtration The Crystar® HiPur ceramic pool microfiltration membrane

From Ok Pool Reform, we recommend the company Crystar Filtration with its ceramic dead-end membrane filtration technology for pool water treatment.

Active ceramic for SPA disinfection

Disinfection of SPA water with active ceramics

How is the SPA water treatment with active ceramics?

La active ceramics, eliminates the traditional use of all chemical products to switch to disinfection that works mechanically.

The use of germicidal ceramics is intended for the decontamination of SPA water. The advantages of this new filtering system are innumerable.

Advantages of active ceramic spa water disinfection

Benefits of SPA water treatment with ceramics

- Firstly, the technology has the advantage of not containing any chemical products..

- Likewise, it offers a healthy and anti-allergic bath water with a pH that is respectful of the skin since it ranges between 5,5 and 6, corresponding to the natural pH of the skin. For this reason, it is ideal for people who do not tolerate chlorine, bromine and other chemicals.

- On the other hand, its operation is autonomous and regular, without any type of continuous treatment, thus, the absence of maneuvers eliminates any risk of device failure.

- Additionally, thanks to the fact that with this system the dirt accumulates in the wastewater, we can reuse the water in nature or return it to the network,

- Finally, this results in a notable reduction in consumption and an optimization of water treatment using active mineral ceramics.

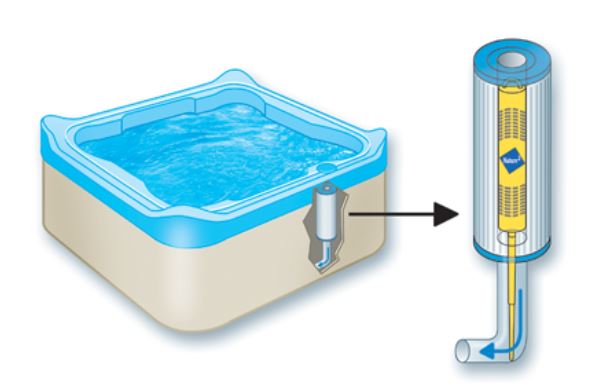

Zodiac Nature 2 Spa: water treatment equipment with active mineral ceramic

What is Nature 2 Spa Mineral Purification Cartridge for Spas?

The Nature 2 Spa mineral purification cartridge for spas is a water treatment using active mineral ceramic. Nature 2 spa works without electricity.

Natural treatment: Nature² Spa is derived from Nature² technology.

Thanks to the action of its minerals (ceramic, zinc and silver), this water treatment is the most effective means to obtain increasingly pure water. The oxidizing mineral particles of the Nature² Spa cartridge are combined with the usual Nature² Express disinfectant.

The Zodiac Nature² mineral water spa purifier, which uses active mineral ceramics and works without electricity, its function is based on the circulation of water through a cartridge containing ceramic balls.

Minerals continually fight in the spa against bacteria, viruses and algae that develop in the water.

The cartridges are inserted in the center of most spa filters. This cartridge can work in two ways: suction or pressure. For all types of spa up to 4 m3.

How active ceramic spa water disinfection works

Technical characteristics

- Water flow: Adapts to all types of spas•

- Volume of treated water (spas): 0 – 4 m3

- Max. temperature Operating water temperature: 35 °C

- Installation: Inside your spa's cartridge filter

- Cartridge weight: 100g

- Dimensions (D x H): Diameter: 3,8 cm / H = 16 cm

- Compatible with most water treatments (chlorine, salt electrolysis, UV, active oxygen, ozone...).

Description for the use of Nature2 SPA

- Type of disinfectant to use: Active oxygen (granular or liquid), ozone, UV, chlorine (all types: organic or inorganic)

- Cartridge autonomy: 4 months from placement in the cartridge filter

- Compatibility: Nature² Spa is not compatible with: bromine and its derivatives, non-chlorine disinfectants such as PHMB (biguamides), other products containing copper. and with certain anti-stain and metal capture products

Operating phases active ceramic spa water disinfection.

- The technological innovation is concentrated in a disinfectant cartridge, inside which there are active ceramic granules. The granules, similar to rice grains, have a germicidal surface as a result of a special nanotechnology treatment, internationally patented.

- The surface of the ceramic has areas subject to the discharge of electrons that destroy most of the organisms with which it comes into contact, with a success rate that in some cases exceeds 99,9999%. The discharge of electrons on the surface is obtained from two nano-layers of oxide and salts, which influence each other in certain proportions and positions.

- The first layer, called the receiving support, attracts and discharges electrons into the active surface layer. This decompensation of electrons leads to a restoration of balance that forces electrons to be subtracted from the microorganisms with which the ceramic comes into direct contact. In this way, the electrons from the upper layers reactivate the filter surface with the same percentage of efficiency.

How to install the SPA cartridge filter purifier

Installation of the zodiac nature² mineral purifier water spa that uses active mineral ceramic

- Easy to use: The Nature² Spa cartridge is autonomous for up to 4 months (depending on use).

- It is installed directly in the spa filter cartridge and the diffusion of its mineral agents is carried out autonomously.

- Therefore, the Nature² cartridge slides directly into the spa's cartridge filter. Use the positioning rods to place the Nature² cartridge in the center of the filter.

Buy The special spa mineral purification cartridge

Contact ceramic purification cartridge for spa

Subsequently, We indicate the official page of the product of Zodiac Nature2 for SPA ceramic microfiltration.